Mitigating risk in rare earth metals supply chains is essential for a just energy transition, say Kevin Braine and Oliver Stern

The ongoing climate emergency, the impact of Russia’s war on Ukraine on the energy sector, and COP 27 have all pushed energy transition to the top of the agenda this winter.

Governments, businesses and consumers across Europe are looking at the future of energy generation with newfound urgency.

As a consequence, managing complex rare earth metals supply chains, which are necessary for energy transition, has become increasingly vital.

Just as the industrial revolution relied on coal and steel, the anticipated energy transition revolution will require the exploitation of the world’s reserves of rare earth minerals. This surging demand is a clear opportunity for UK businesses, but it is not without risks.

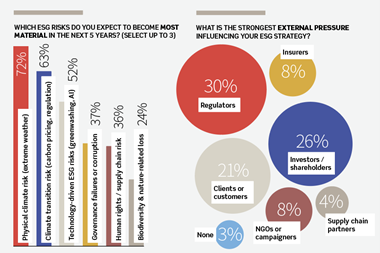

National regulators, multilateral institutions, metal trading exchanges, consumers and investors are putting pressure on producers for greater supply chain transparency and demonstrable steps to limit exposure to environmental damage and “social” liabilities, particularly associated with human rights.

Effective supply chain management is no longer about ensuring supply continuity and maximising efficiency. A more nuanced approach that identifies and responds to risks is required.

Understanding the challenges

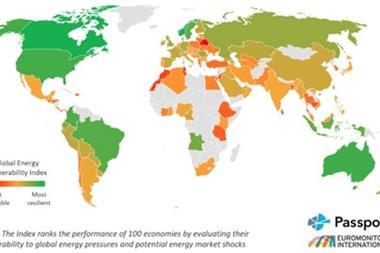

The mining and metals space has always faced a fundamental supply chain challenge. To put it simply, the resources that are of a high enough concentration to be economically exploited cannot be moved. Mining firms must operate where the deposits are located.

The concentration of cobalt deposits in the Democratic Republic of the Congo (DRC) is perhaps the starkest example of mineral scarcity and geographic location driving risks for those operating in the country.

The DRC presents operators with a myriad of risks, such as security of tenure and political and social risks, that look to remain daunting for the foreseeable future, despite the anticipated surge in demand for the country’s mineral deposits.

The production, refining and smelting of rare earth metals also faces a profound provenance challenge. In areas where artisanal production involves large numbers of producers operating across a wide area, understanding who produced what and under what conditions remains a real challenge to supply chain transparency.

One example of the difficulty associated with doing business in such challenging markets, while navigating an evolving regulatory environment, is Germany’s new Lieferkettensorgfaltspflichtengesetz Act (Supply Chain Due Diligence Act), which comes into effect in January 2023.

Although largely untested, the Act is designed to make businesses responsible for identifying and mitigating human rights and environmental risks in their supply chains. This kind of regulatory scrutiny is only set to increase.

Minimising risk exposure

Managing these risks requires careful planning and analysis. Before this can be tackled, businesses need to get a clear view of their own supply chains. This is no small task, but it is one that companies should take seriously and have a clear strategy to deal with.

Any solution will need to be tailored to the needs of the individual business in question, but the main obstacle to be overcome is the sheer scale of the task, which for many organisations can at first appear a major barrier to progress.

Understanding the supply chain involves careful gathering, organisation, and management of an often-massive amount of data.

To manage all this data, many businesses are already beginning to make use of specialised artificial intelligence. Combining this sophisticated AI with human intelligence will help leaders understand, manage and respond to supply chain risk more effectively.

This hybrid approach, using the latest tech, as well as experts with deep subject-matter knowledge and experience of national, regional and global supply chains, will likely be the only cost-effective way for businesses to approach a task of this scale, but it also comes with challenges of its own.

Integrating these two elements will require new systems and infrastructure. Many firms will need to begin investing now in the kind of integrated and flexible workflow software platforms that will allow them to meet these requirements.

It’s important to stress, too, that this isn’t a one-time audit. The risk management system will need to be adaptable and ongoing and should take into consideration further legislative changes.

There will almost certainly be cases where national and regional legislations must be integrated into a company’s plans, and it is, therefore, vital for businesses to keep track of the latest updates to ensure they remain compliant.

The regulations that are driving change require careful monitoring and the proactive identification of risk. We know from our experience as “post-event” investigators that waiting for a risk to become material can be a costly and reputationally damaging decision.

We also know that in a capital-scarce environment, investors are increasingly demanding greater transparency and risk mitigation before they commit funds. There is nothing on the horizon to suggest that this trend will change course.

Leading the way

The UK’s energy transition represents a golden opportunity for the UK metals industry to meet the vision of the UK Metals Council for a “modern and progressive UK Metals Industry … supplying high-quality, innovative and competitively priced products to a wide range of customers, locally and internationally.”

This requires a transition from supply chain management to a more robust, proactive and risk-focused management approach.

While the challenges inherent in the mining and metals sector mean that the industry supply chains will be challenging for a long time to come, change is on its way and the scale of the task should not deter action.

Companies that fail to act now are effectively taking on more commercial and reputational risk, whether they realise it or not.

Although the empirical evidence is still emerging, anecdotally it appears clear that those firms which are proactively engaging and responding to the risk are already better placed commercially to succeed in this changing market.

Kevin Braine is managing director and Global head of Research and Operations, Compliance Risk and Diligence, Kroll. Oliver Stern is managing director, Forensic Investigations and Intelligence, Kroll.

No comments yet